The tubes present no hazard to the human health since no CFC or HCFC is used in their production and have a very low VOC level. They are considered environmental friendly products (with low Ozone Depletion Potential – ODP – and Global Warming Potential – GWP) and comply with the LEED requirements, helping buildings to get more LEED points.

The Aerofoam® Flexible Elastomeric Foam has a very good dimensional stability and offer an excellent protection against condensation, thermal loss and sound transfer.

Aerofoam® Elastomeric Thermal Insulation Tubes complies to its ongoing improvement of quality, technological integrity, and outstanding performance in demanding settings with the FM approval and satisfies the most stringent safety and fire-resistance standards. FM approval for Aerofoam® NBR used on the exterior of non-combustible pipes or ducts increases our clients’ faith in Aerofoam further.

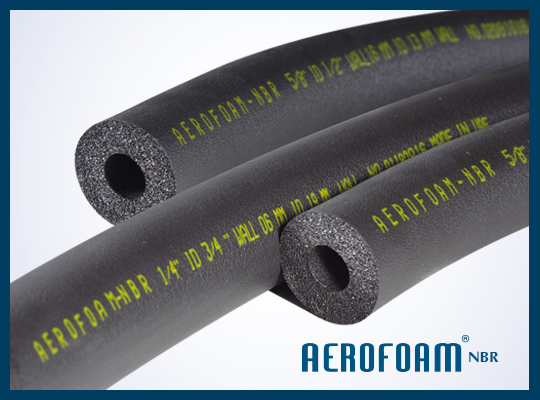

Aerofoam® Flexible Elastomeric Foam is made from closed cell elastomeric foam, which has a micro-cell, non-porous structure and closed cell content bigger than 90%. They cover a wide range of diameters and thicknesses, matching with most used pipe sizes. The Aerofoam® Flexible Elastomeric Foam has a very good dimensional stability and offers an excellent protection against condensation, thermal loss and sound transfer. The flexibility of the tubes and the powder applied inside them, allows a low friction movement and improves the installation time significantly. The tubes are also available without the powder according to the customers’ requirements.

APPLICATIONS

- Elastomeric Tubes

- Aerofoam® Tape (Aluglass)

- Aerofoam® Glue

- Aerofoam® Foam Tape